What is a Vapor Chamber radiator

A VCH consists of a sealed copper plate filled with a small amount of fluid (such as deionized water) to allow rapid heat transfer from the heat source. Homogeneous plate radiators have an internal support structure that prevents the cavity wall from bending. Homogeneous plate is formally known as a heat pipe. It is one of the best cooling options for a radiator substrate and is commonly used in high power equipment. The uniform temperature plate is generally combined with the fin to achieve efficient heat dissipation.

VCH can be synthesized with aluminum or copper radiators, and the easiest way to do this is to weld a uniform temperature plate to the bottom of an extruded radiator. There is also a more efficient method of heat dissipation is to weld the stamped fins directly to the surface of the uniform temperature plate. In order to improve product integrity, clasp fins and zipper fins are commonly chosen.

How does the Vapor Chamber work?

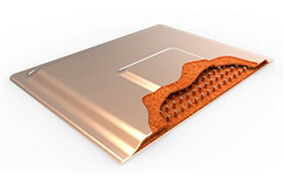

The homogeneous vapor chamber is composed of a sealed vacuum vessel with a micro structure on the inner wall and a small amount of working fluid in equilibrium with its own gas. Vacuum vessels are usually made of copper and sealed around the perimeter. The microstructure of the inner wall can be made of many different substances. The most common method is to sinter copper powder onto the inner wall of the container. Many fluids can be used as VCH working fluids. However, in most CPU, GPU, and LED cooling applications, water is often chosen as the working fluid due to its high latent heat, high surface tension, high thermal conductivity, and due to cost and environmental considerations.

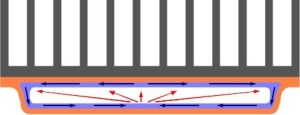

The low pressure in the chamber causes the fluid to evaporate at a temperature much lower than its normal boiling temperature. When heat is applied to the VCH, the fluid near that location immediately evaporates and fills the entire chamber (driven by differential pressure). When the vapor comes into contact with the cooler inner surface, the vapor condenses and releases heat. The condensed fluid returns to the heat source through capillary action of the microstructure. As the vaporization and condensation cycles are repeated, heat from the heat source is moved throughout the chamber, resulting in a uniform temperature distribution on the chamber surface.

The benefits of uniform Vapor Chamber

Under proper design, the heat dissipation of uniform temperature plate is 10-30% higher than that of copper radiator. In some applications, the uniform temperature board can reduce the temperature to an ideal level without installing a fan on the top of the heat sink, improving the reliability of the heat dissipation system and eliminating noise.