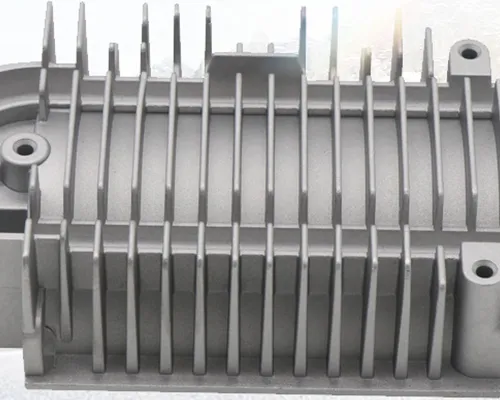

Die-cast heat sinks are pivotal components within the realms of both industrial and civilian thermal management. Utilizing high-pressure die-casting technology, molten metal is injected into a mold cavity at high speed and pressure to form the product in a single step. Its core strength lies in the high degree of freedom in structural design—by meticulously adjusting fin density, thickness, and layout, an optimal balance between heat dissipation area and spatial footprint can be achieved. This makes it particularly suitable for scenarios with stringent demands on thermal performance, such as electronic devices and battery thermal management systems in new energy vehicles.

In terms of materials, the application of lightweight, high-thermal-conductivity materials like aluminum alloy allows die-cast heat sinks to ensure efficient heat dissipation while significantly reducing overall weight, aligning with the modern trend towards equipment lightweighting. Furthermore, the integrated die-casting molding process grants it excellent mechanical stability, enabling it to withstand vibrations and impacts under complex operating conditions and ensuring long-term, reliable performance.

Medical industry heat sink

Laser module heat sink

LED Heatsink