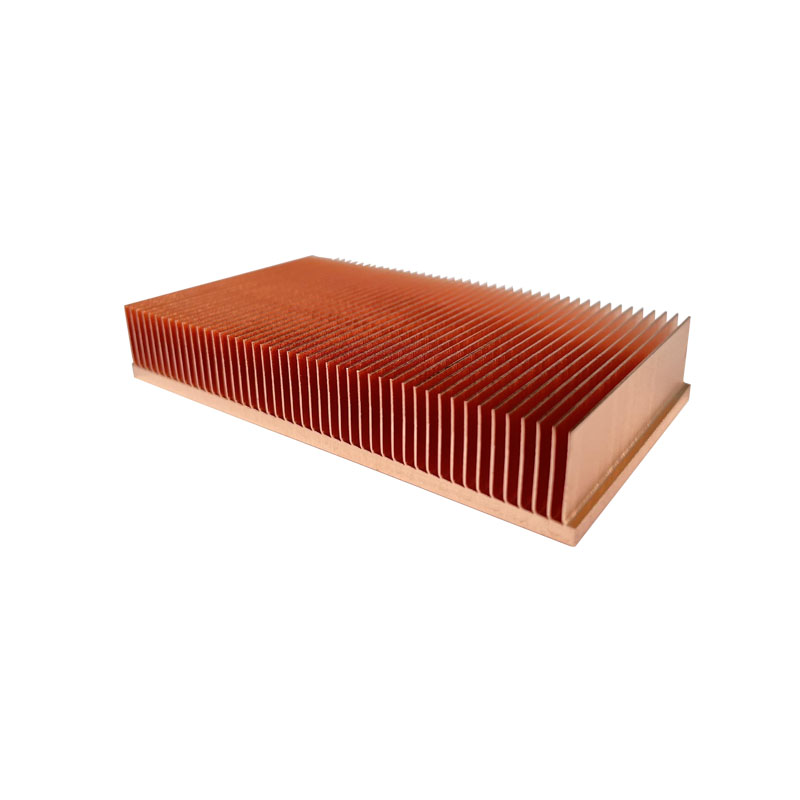

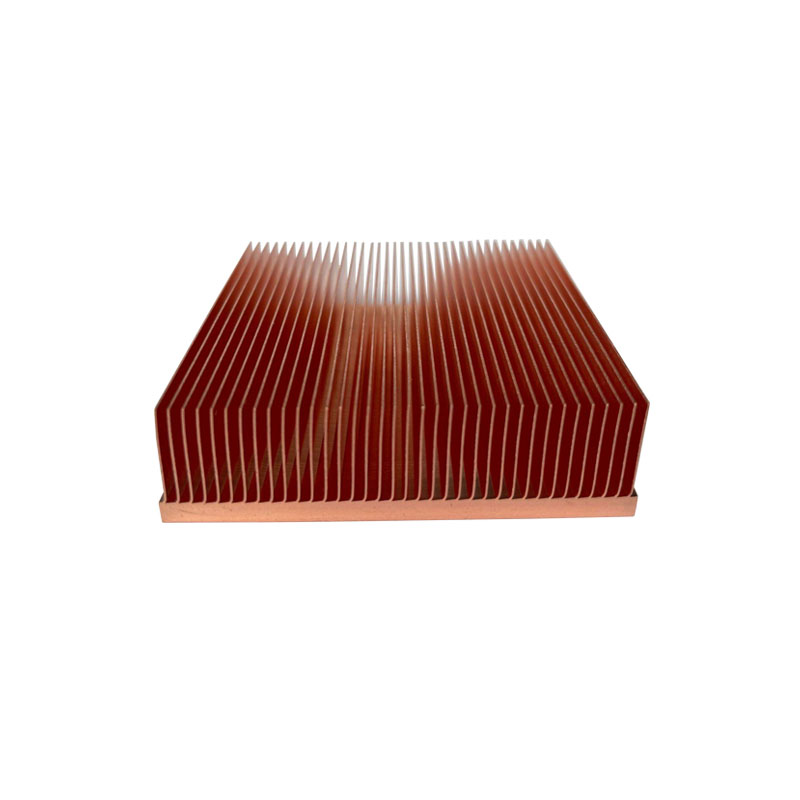

Skived fin heat sinks is a heat dissipation device for the thermal electronic components in electrical appliances, mostly made of aluminum alloy, brass or bronze plate, flake, flake, etc. If it is a side-blown radiator, it should be determined according to the internal air duct structure of the chassis. If you do not know these things about the air duct, then let him blow the heat sink, because the general chassis in the CPU radiator at the same height of the backplane position will have heat dissipation hole, blow shovel teeth heat dissipation fin will be eliminated from the heat dissipation hole of the backplane, more efficient.

Copper skived fin heat sinks is a heat dissipation device for the thermal electronic components in electrical appliances, mostly made of aluminum alloy, brass or bronze plate, sheet, sheet and so on. If it is a side-blown radiator, it should be determined according to the internal air duct structure of the chassis. If you do not know these things about the air duct, then let him blow the heat sink, because the general chassis in the CPU radiator at the same height of the backplane position will have heat dissipation hole, blow shovel teeth heat dissipation fin will be eliminated from the heat dissipation hole of the backplane, more efficient.

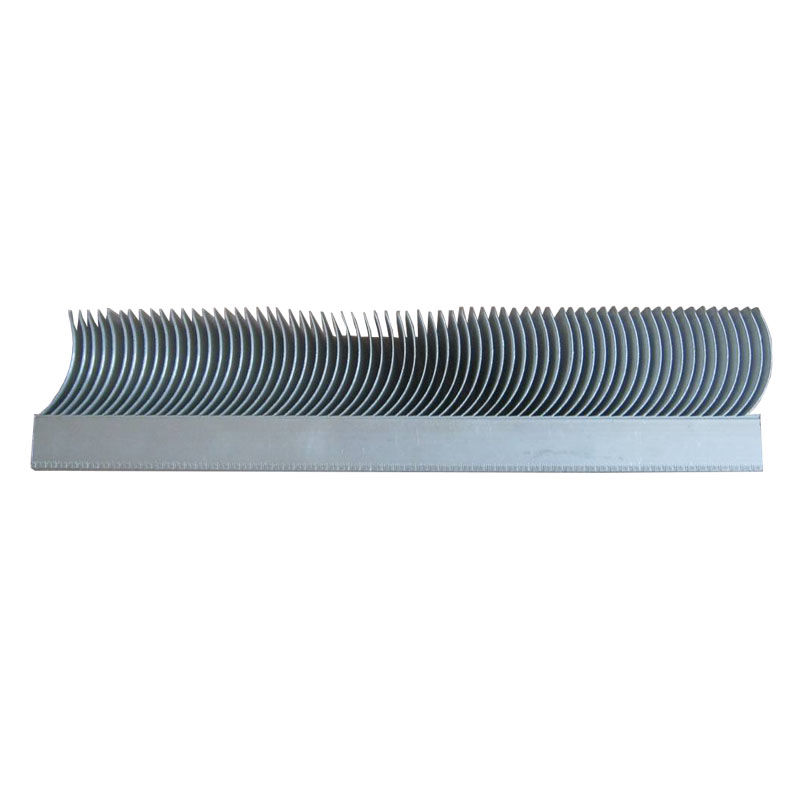

Relieving the radiator of skived Fin spacing can be designed smaller, fin can be thinner, so much for heat dissipation of high power devices, but due to the characteristics of the molding process, each a radiator need from zero processing, that is to say we all can be in the early stage of the design for each project for relieving the radiator parts, including the thickness of the base board, fin height and thickness, Tooth spacing and other data were optimized.

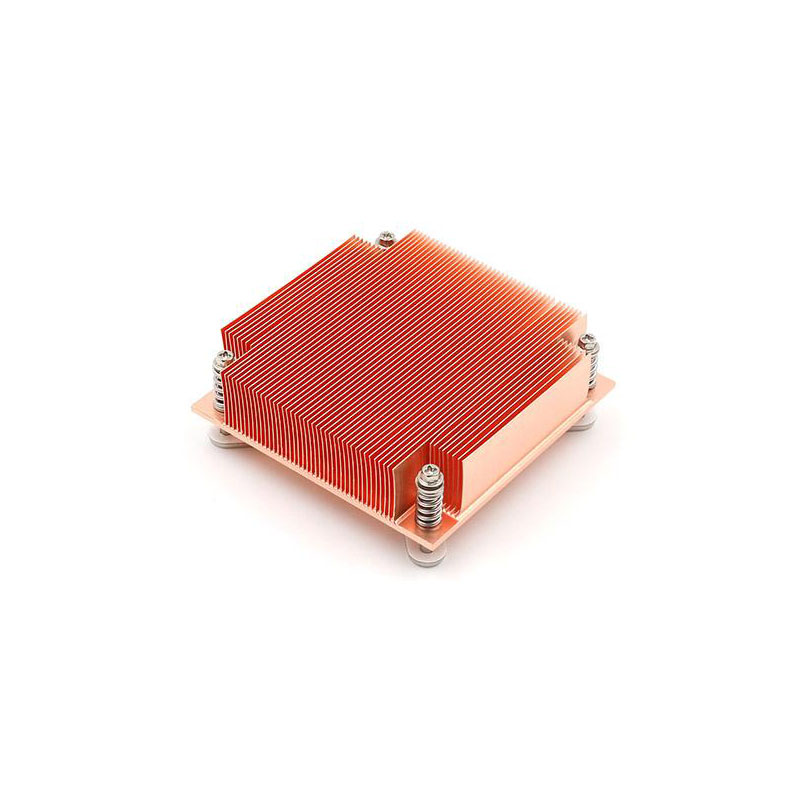

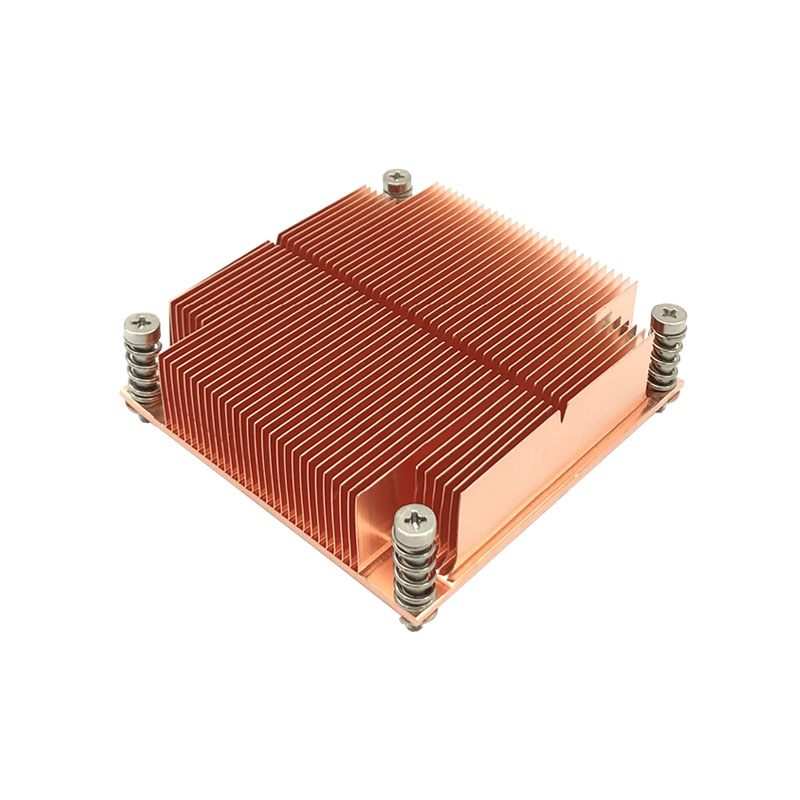

Copper Skived fin heat sinks features:

A special knife (spatula) is used to scoop the blade piece by piece from an aluminum or copper sheet and erect it.

Advantages of Skived fin heat sinks:

Breaking through the limit of the thickness and length ratio of the conventional radiator, the radiator with high density can be produced.

Blade and base are integrated, there is no interface impedance problem, the heat dissipation effect is very good, close to the aluminum extrusion radiator, widely used in the photovoltaic industry, electric vehicles, inverters, communication products, etc.

Disadvantages of Skived Fin radiator:

The processing cost is high, and the waste generated is much, with a certain defect rate, and the product cost is relatively high. When the shovel is a long radiator, there will be a trench of about 4mm every 150mm interval.

Processing capacity of Skived Fin:

Maximum tooth width 800mm, tooth height 100mm.

Tooth pitch: 0.1mm~7.5mm.

Tooth thickness: 0.1mm~7.5mm.

Tolerance of + / - 0.2 mm.

Customized

Provide one-stop service

Radiator / Heat sink / Ultrathin heat pipe / Vapor Chamber / Liquid cooling plate

Requirement Communication

ONE

Determine solution

TWO

Concluding a contract

THREE

Down payment

FOUR

Proofing and validation

FIVE

Mass production processing

SIX

QC & QA

SEVEN

Logistics distribution

EIGHT

Customer satisfaction acceptance

NINE

Customer service

TEN